PE Coating ACP Panel: A Cost-Effective Solution for Modern Construction

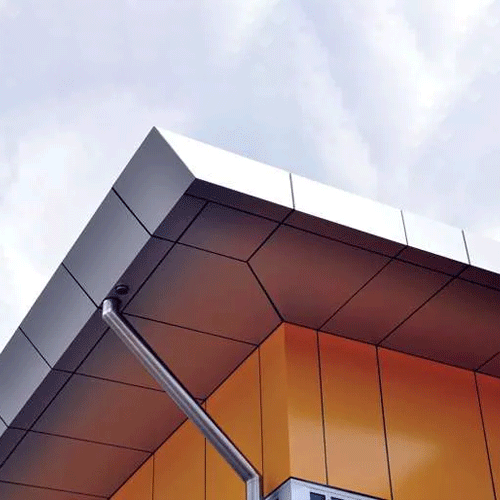

In the world of modern architecture and construction, PE Coating ACP Panel has become a popular material for both interior and exterior applications. Known for its lightweight structure, excellent durability, and smooth surface, PE (Polyester) Coating Aluminum Composite Panels are widely used in commercial buildings, signage, and interior decoration. This article explores what makes PE Coating ACP Panel an ideal choice for various applications, its advantages, and why it is a preferred material in the global market.

What is PE Coating ACP Panel?

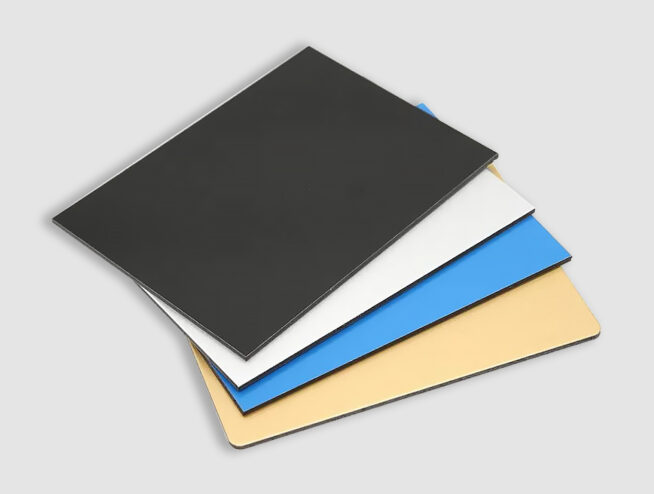

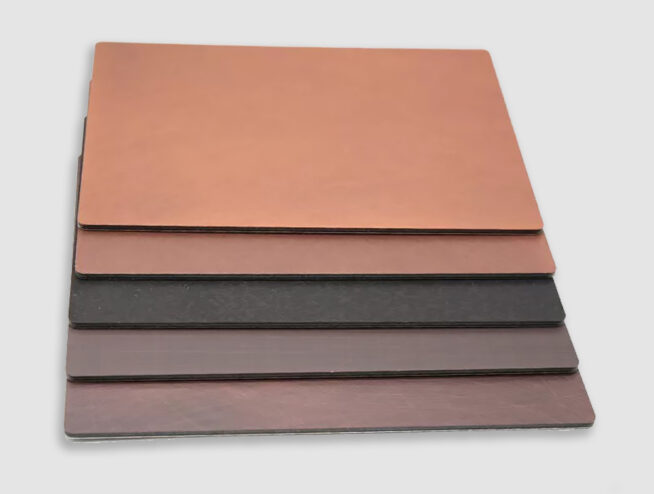

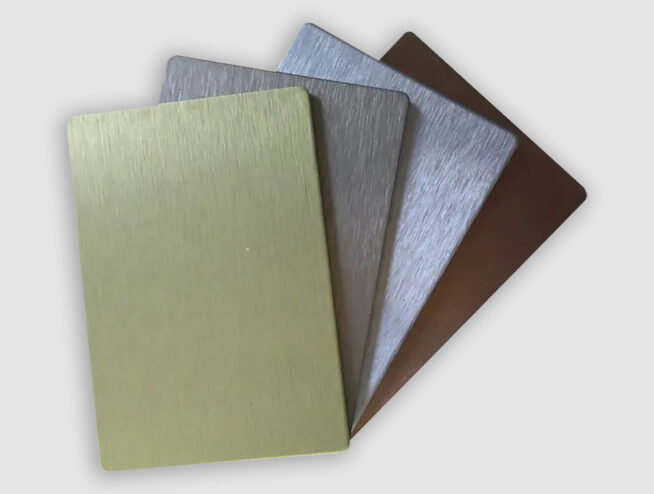

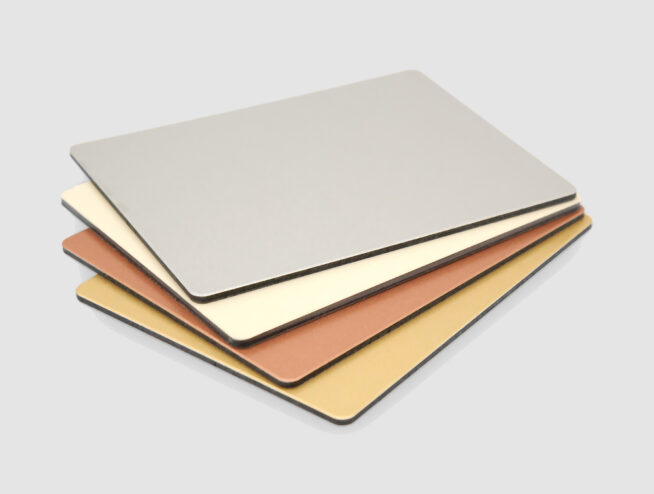

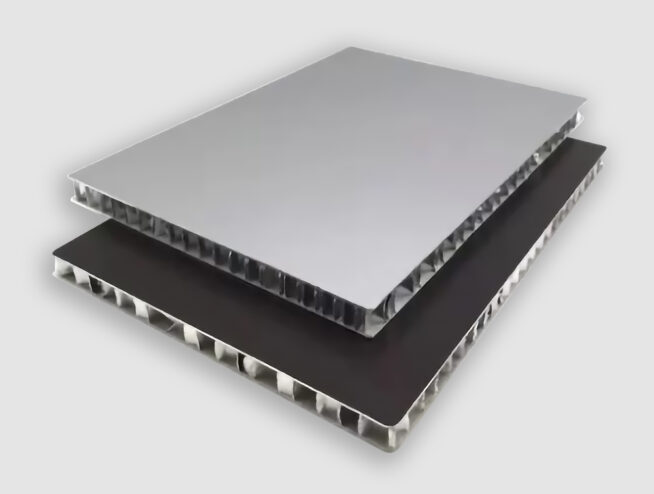

A PE Coating ACP Panel is a type of aluminum composite panel that features a polyethylene core sandwiched between two aluminum sheets. The surface is coated with a high-quality polyester (PE) paint, which provides a smooth finish, weather resistance, and UV protection. These panels are available in various colors, textures, and sizes to suit diverse design requirements.

Advantages of PE Coating ACP Panel

-

Lightweight and Easy to Install

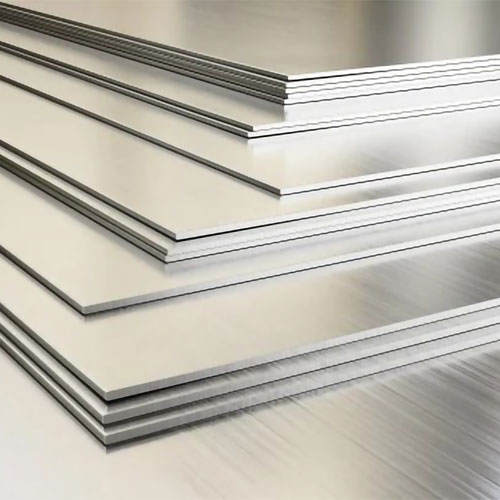

PE Coating ACP Panels are significantly lighter than traditional building materials like steel or solid aluminum sheets. This makes them easy to handle, transport, and install, reducing construction time and labor costs. -

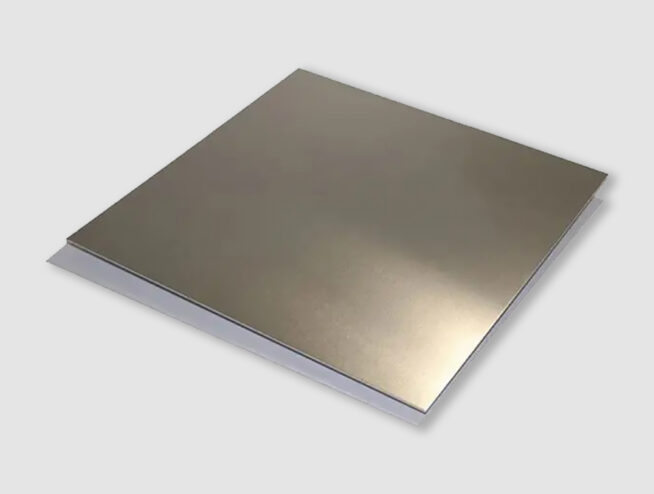

Excellent Surface Flatness

Thanks to advanced coating technology and precise manufacturing, the surface of the PE Coating ACP Panel is exceptionally smooth and flat. This ensures a high-end finish, especially in applications like signage, exhibition displays, and decorative facades. -

Wide Color Range

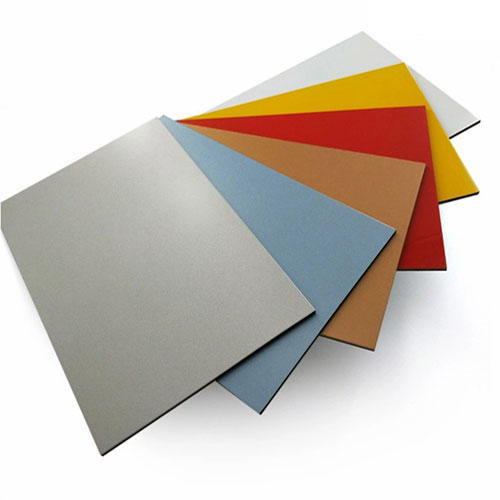

PE Coating allows the application of vibrant and customizable colors. From solid tones to metallic finishes, these panels can match any design concept, making them ideal for branding and creative architecture. -

Cost-Effective

One of the main reasons why PE Coating ACP Panel is so widely used is its affordability. Compared to other cladding or decorative materials, it offers a low-cost yet high-performance solution for a variety of uses. -

Durable Performance

While PE Coating ACP Panels are not intended for extreme weather conditions (unlike PVDF-coated panels), they still offer good resistance against UV rays, corrosion, and daily wear, making them suitable for most indoor and light outdoor environments.

Common Applications of PE Coating ACP Panel

The versatility of PE Coating ACP Panel makes it a go-to material across several industries:

-

Interior Decoration: Ideal for ceilings, partitions, wall panels, and columns.

-

Retail and Commercial Spaces: Used in shop fronts, signage, display stands, and kiosks.

-

Corporate Branding: Applied in logo backdrops, reception areas, and brand color themes.

-

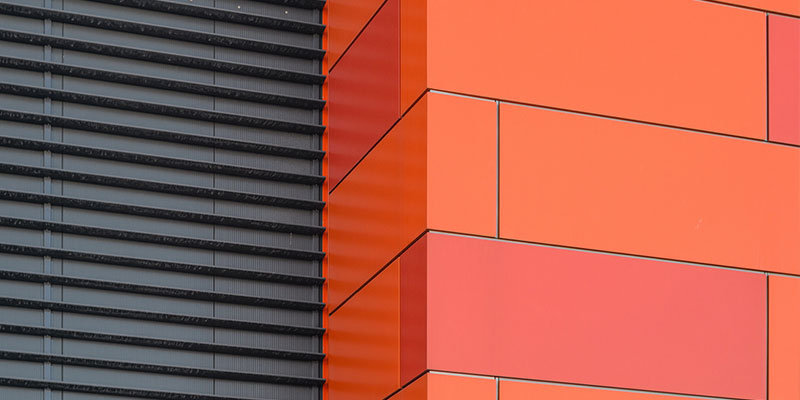

Lightweight Exterior Cladding: While not suitable for high-rise buildings, they perform well in low-rise structures and decorative façades.

PE Coating ACP Panel vs. PVDF Coating ACP Panel

A common question from clients is the difference between PE Coating and PVDF Coating ACP Panels. While both are aluminum composite panels, the key difference lies in the surface paint:

-

PE Coating ACP Panel: Designed for indoor and light outdoor applications. It is more affordable and offers a good balance between performance and cost.

-

PVDF Coating ACP Panel: Intended for outdoor use, especially in harsh weather. It provides better resistance to UV, acid rain, and aging but comes at a higher cost.

For clients with indoor projects or budget-conscious developments, PE Coating ACP Panels offer the best value.

Environmental and Safety Features

Modern PE Coating ACP Panels are manufactured with environmental standards in mind. The polyethylene core can be made from eco-friendly materials, and the aluminum layers are recyclable. Additionally, manufacturers can provide fire-resistant versions of PE core panels to meet safety regulations in public or commercial buildings.

Why Choose Alumetal for PE Coating ACP Panel?

At Alumetal, we specialize in producing high-quality PE Coating ACP Panels tailored to meet the needs of international clients. With advanced coating lines, strict quality control, and a dedicated R&D team, we ensure our panels not only meet but exceed industry standards. Whether you need custom colors, specific sizes, or bulk orders, we are ready to provide competitive solutions with fast delivery.

Conclusion

The PE Coating ACP Panel continues to gain popularity across various industries thanks to its affordability, versatility, and aesthetic appeal. Whether you’re an architect, contractor, or signage manufacturer, this panel offers a practical solution that doesn’t compromise on appearance or functionality. When chosen wisely and used in the right environment, PE Coating ACP Panels can significantly enhance the visual and structural aspects of any project.

For more details about our PE Coating ACP Panels, feel free to contact our team or request a sample. We are here to support your design ambitions with reliable and affordable material solutions.