ACM Aluminum Composite Material

Aluminum Composite Material (ACM) is a versatile and widely used construction material known for its durability, lightweight properties, and aesthetic appeal. It consists of two thin layers of aluminum enclosing a non-aluminum core, which is typically made of polyethylene (PE) or a fire-retardant material. This sandwich structure combines the best properties of both aluminum and the core material, resulting in a product that is strong, lightweight, and easy to work with.

ACM Composition and Structure

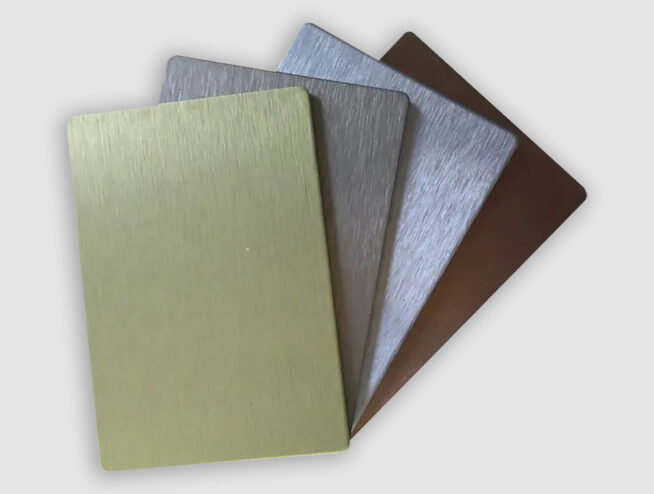

ACM panels are manufactured through a process of bonding aluminum sheets to a core material under high pressure and temperature. The outer aluminum layers can be coated with various finishes, such as paint, anodized layers, or other coatings to enhance their appearance and resistance to weathering and corrosion. The core material, usually polyethylene or a fire-retardant mineral core, provides additional strength and impact resistance.

ACM Key Features and Benefits

Lightweight: One of the primary advantages of ACM is its lightweight nature. This makes it easier to handle and install compared to solid aluminum sheets or other construction materials.

Durability: ACM panels are highly resistant to weathering, corrosion, and UV radiation. This makes them suitable for both interior and exterior applications, ensuring longevity and minimal maintenance.

Versatility: The panels can be easily cut, bent, and shaped to fit a wide range of architectural designs. They are available in various colors, finishes, and textures, allowing for creative and innovative applications.

Cost-Effective: Compared to solid metal sheets, ACM is more cost-effective due to its lightweight nature and ease of installation, which reduces labor and transportation costs.

Thermal and Sound Insulation: The core material of ACM provides good thermal insulation properties, helping to improve the energy efficiency of buildings. It also offers sound insulation, contributing to a quieter indoor environment.

Aluminum Composite Material Applications

ACM is used in a variety of applications across different industries, including:

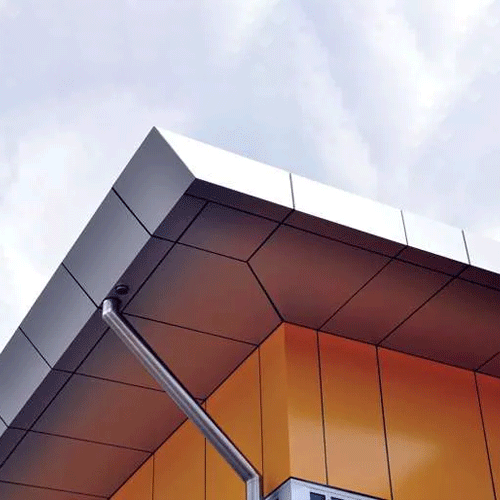

Building Facades: ACM panels are commonly used for cladding building exteriors, providing a modern and sleek appearance while protecting the structure from environmental elements.

Signage: Due to their smooth surface and excellent printability, ACM panels are popular in the signage industry for both indoor and outdoor signs.

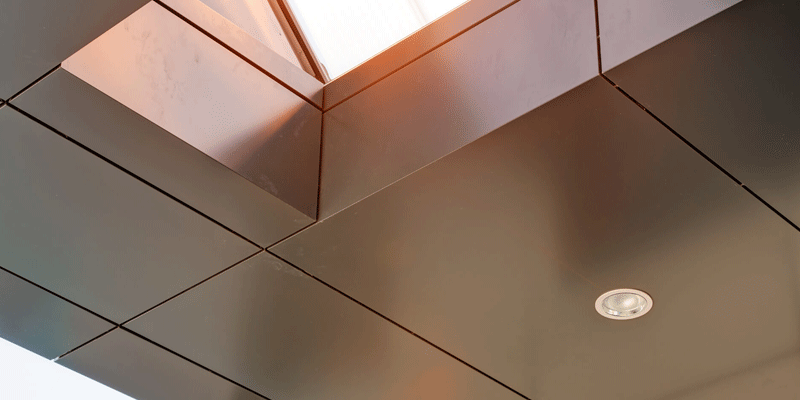

Interior Design: ACM is used in interior applications such as wall panels, partitions, and ceiling panels, offering a contemporary look and durable finish.

Transportation: The lightweight and durable properties of ACM make it suitable for use in the transportation industry, including in the construction of vehicle bodies and trailers.

Environmental Considerations

With growing environmental concerns, ACM manufacturers are focusing on producing more sustainable and eco-friendly products. Some ACM panels now feature recyclable materials and low-VOC (Volatile Organic Compounds) coatings, contributing to greener building practices.

Conclusion

Aluminum Composite Material (ACM) stands out as a superior construction material due to its combination of strength, lightweight properties, and versatility. Its wide range of applications, from building facades to signage and interior design, highlights its importance in modern architecture and construction. As the industry moves towards more sustainable practices, ACM continues to evolve, offering environmentally friendly options that meet the needs of contemporary building standards.