Anti Static Aluminum Composite Panel: The Ideal Solution for Dust-Free Environments

In today’s high-tech industries, the need for clean, static-free environments is greater than ever. Electronics manufacturing, laboratories, pharmaceutical production, and data centers all require materials that prevent static electricity buildup to maintain safety and product integrity. One of the most effective and reliable materials for such applications is the Anti Static Aluminum Composite Panel.

What is an Anti Static Aluminum Composite Panel?

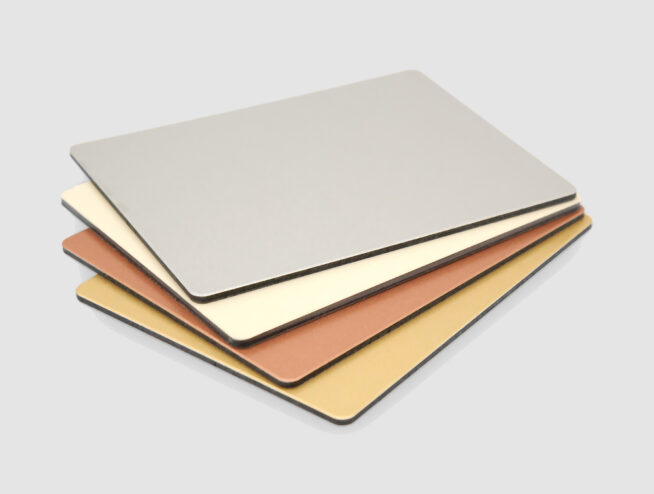

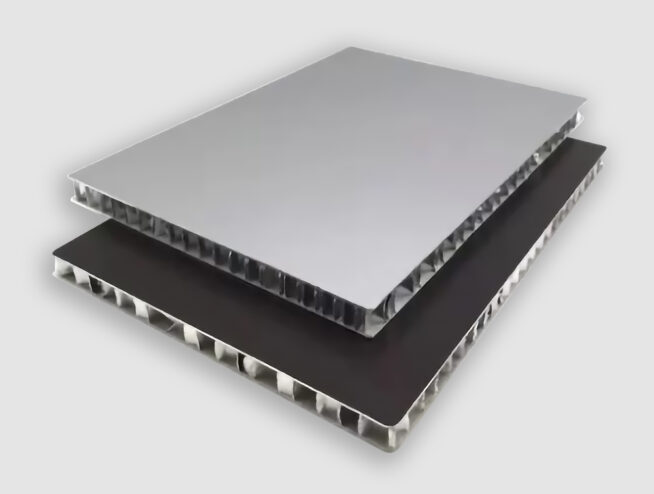

An Anti Static Aluminum Composite Panel (ACP) is a type of aluminum composite material that is specially engineered to dissipate static electricity. Unlike conventional ACPs, which may attract dust and create static buildup, anti static ACPs are coated with a special conductive layer that neutralizes static charges.

These panels consist of two aluminum sheets bonded to a non-aluminum core, typically made of polyethylene or fire-retardant material. The key difference lies in the surface coating — the anti-static layer — which gives the panel its dust-repelling and static-dissipating properties.

Key Features and Benefits

-

Anti Static Functionality

The primary advantage of this product lies in its ability to prevent static electricity accumulation. In environments where even a small electric discharge can damage sensitive equipment or cause contamination, using an Anti Static Aluminum Composite Panel is a proactive measure to ensure safety and product quality. -

Dust Repellence

Because static electricity attracts airborne particles, ordinary panels can quickly become dirty, compromising cleanliness. Anti static ACPs eliminate this issue by resisting dust buildup, making them ideal for cleanrooms and sterile areas. -

Durability and Strength

Anti static ACPs maintain all the structural advantages of traditional ACPs, including excellent impact resistance, weather durability, and high strength-to-weight ratio. This makes them suitable for both interior and exterior applications. -

Easy Maintenance

Thanks to their anti-dust surface, these panels require minimal cleaning, reducing maintenance costs over time. They also retain their appearance longer, maintaining a clean and professional look. -

Fire Resistance (Optional)

Many anti static ACPs are available in fire-resistant versions, meeting international safety standards, especially crucial in sensitive environments.

Common Applications

The Anti Static Aluminum Composite Panel is widely used in environments where static electricity must be controlled or eliminated. Typical applications include:

-

Electronics Factories

To protect semiconductors and circuit boards from electrostatic discharge (ESD), walls and partitions made from anti static ACP are often installed. -

Clean Rooms

In pharmaceutical production and laboratories, preventing contamination is critical. Anti static ACPs provide a hygienic and stable solution. -

Data Centers

Servers and storage systems are highly sensitive to static discharges. Using anti static materials in wall cladding and partitions helps protect equipment. -

Control Rooms and High-Tech Facilities

Where high-value instruments operate continuously, anti static surfaces contribute to a safer and more reliable working environment.

Why Choose Our Anti Static Aluminum Composite Panel?

Our company specializes in producing high-performance Anti Static Aluminum Composite Panels tailored to meet the needs of various industries. Here’s why customers choose us:

-

Advanced Coating Technology

We apply a uniform anti-static layer using advanced techniques to ensure consistent conductivity and dust resistance across the entire surface. -

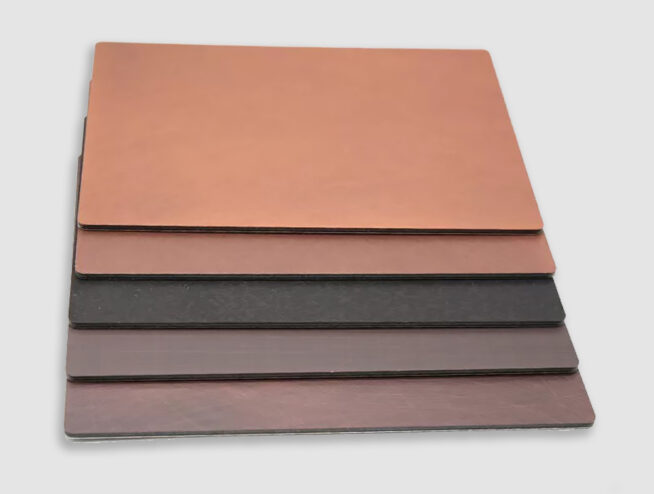

Customizable Specifications

Panel thickness, color, and size can be tailored to meet your specific project requirements, including options for fire resistance and UV protection. -

Strict Quality Control

Every batch of our anti static ACPs undergoes rigorous testing to ensure compliance with international standards such as ISO, ASTM, and RoHS. -

Global Supply Capability

With years of export experience and partnerships across multiple continents, we can efficiently deliver to your project site, no matter the location.

Installation and Maintenance Tips

Installing an Anti Static Aluminum Composite Panel is similar to that of standard ACPs. However, attention must be given to ensure grounding of the panels to maximize their static-dissipating function. Proper grounding ensures any electrical charge is safely conducted away.

For maintenance, a soft cloth with water or neutral detergent is sufficient to keep the panels clean. Avoid using abrasive cleaners, which might damage the anti static coating.

Conclusion

In sensitive environments where safety, cleanliness, and performance are non-negotiable, the Anti Static Aluminum Composite Panel proves to be an essential building material. Its ability to prevent static buildup, resist dust, and offer long-term durability makes it an investment in operational safety and efficiency.

If your project requires high-performance materials that can meet strict technical and safety standards, don’t hesitate to contact us for samples or technical consultations. Our Anti Static Aluminum Composite Panel solutions are trusted by professionals worldwide, and we’re ready to support your next project with reliable, custom-engineered materials.