Aluminum Honeycomb: Applications and Benefits

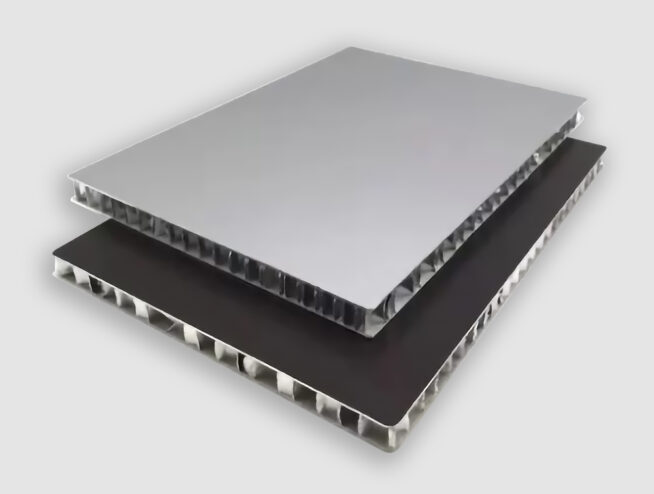

Aluminum Honeycomb Panel is a specialized material renowned for its remarkable strength-to-weight ratio, durability, and versatility. This lightweight yet sturdy material is constructed from thin aluminum sheets that are bonded together in a hexagonal pattern, resembling the structure of a natural honeycomb. This design imparts exceptional mechanical properties, making Aluminum Honeycomb Panel a valuable component in various industries.

Aerospace Industry

One of the primary applications of Aluminum Honeycomb Panel is in the aerospace industry. Aircraft structures benefit immensely from the material’s high strength and low weight, which are crucial for enhancing fuel efficiency and performance. Aluminum honeycomb is used in a variety of aircraft components, including:

- Aircraft panels: Providing structural integrity while minimizing weight.

- Cabin interiors: Offering lightweight partitions and flooring solutions.

- Engine nacelles: Contributing to the overall reduction of aircraft weight without compromising on strength.

Automotive Industry

In the automotive sector, aluminum honeycomb is used to improve vehicle safety and efficiency. It is often found in:

- Crash absorption zones: Helping to absorb impact energy during collisions, thereby enhancing passenger safety.

- Structural reinforcements: Providing additional strength to critical areas of the vehicle while keeping the weight low.

- Interior components: Such as dashboards and door panels, where weight savings are essential for improving fuel efficiency.

Construction and Architecture

Aluminum honeycomb panels are also widely used in construction and architectural applications. They offer a combination of aesthetic appeal and structural benefits, making them ideal for:

- Building facades: Providing an attractive and durable exterior finish.

- Interior wall cladding: Offering a lightweight and strong alternative to traditional materials.

- Roofing and ceiling panels: Ensuring strength without adding significant weight to the structure.

Marine Industry

In the marine industry, aluminum honeycomb panels are valued for their corrosion resistance and lightweight properties. They are used in:

- Boat hulls and decks: Offering strength and buoyancy while reducing overall weight.

- Interior partitions: Providing durable and lightweight solutions for marine environments.

- Bulkheads: Contributing to the structural integrity of ships and boats.

Renewable Energy

Aluminum Honeycomb Panel is increasingly being used in the renewable energy sector, particularly in the production of solar panels and wind turbine blades. Its lightweight nature and structural strength help improve the efficiency and durability of these renewable energy systems.

Benefits of Aluminum Honeycomb

The widespread use of aluminum honeycomb across various industries is attributed to several key benefits:

- High Strength-to-Weight Ratio: The honeycomb structure provides exceptional strength while maintaining minimal weight.

- Durability: Aluminum honeycomb is resistant to corrosion, impact, and environmental factors, ensuring a long lifespan.

- Versatility: The material can be customized to meet specific requirements, making it suitable for a wide range of applications.

- Energy Absorption: Its ability to absorb impact energy makes it ideal for safety applications in the automotive and aerospace industries.

- Thermal Conductivity: Aluminum’s natural thermal conductivity can be advantageous in applications requiring efficient heat distribution.

Conclusion

Aluminum Honeycomb Panel is a versatile material that offers significant advantages in various industries, from aerospace and automotive to construction and renewable energy. Its unique combination of lightweight properties, strength, and durability makes it an essential component in modern engineering and design. As technology advances, the applications of Aluminum Honeycomb Panel are likely to expand, driving innovation and efficiency across multiple sectors.